Drone solutions provide critical visual and thermal data on the condition of power plants, so professionals can identify risks and resolve them quickly, without interrupting operations. The ability of a drone to cover great distances and provide high-resolution aerial imagery has enabled many companies to optimise their efficiency when completing dangerous or time-consuming tasks

The Solar Energy Industry

Solar energy has been the preferred solution when considering the many renewable energy sources. To meet energy demands, solar power companies must install thousands of solar panels distributed over large areas that are usually highly irradiated. The integration of drone technology has undoubtedly improved the efficiency and accuracy of the entire inspection process.

Drones are continuously being used in solar panel inspection to improve inspection operations, especially in areas that are highly irradiated and create a number of problems for on-site teams. The use of drones allows teams to reduce inspection time by around 70%, a significant reduction when compared to traditional methods.

Solar Photovoltaic System Inspection

Get real-time temperature readings of solar panels using drones equipped with visual and radiometric thermal sensors to immediately identify anomalies.

Traditional Challenges in Solar PV System Inspection

Inspection of solar panels from the ground can be slow and incomprehensible due to perspective limitations and handheld devices.

Inspection data are qualitative records that may not be digitized, which can cause problems in record keeping and take more time from inspection to repairs.

How do Drones Inspect Solar PV Systems?

Automated flight paths can be configured to perform complete and repeatable inspections of solar panels without safety risks to work teams.

Drones allow teams to view temperature readings and visible light images in real time, so that any hotspots on photovoltaic components can be identified immediately.

Drone inspection data is digitised and ready for further analysis or record-keeping, significantly improving efficiency.

Assessment of solar panels

First, the inspection team needs to confirm the dimensions of the solar panel before preparing an effective plan. Each inspection has its own characteristics, but there are some common aspects to be observed during the evaluation stage. These include the area, the number of panels installed and the energy production capacity.

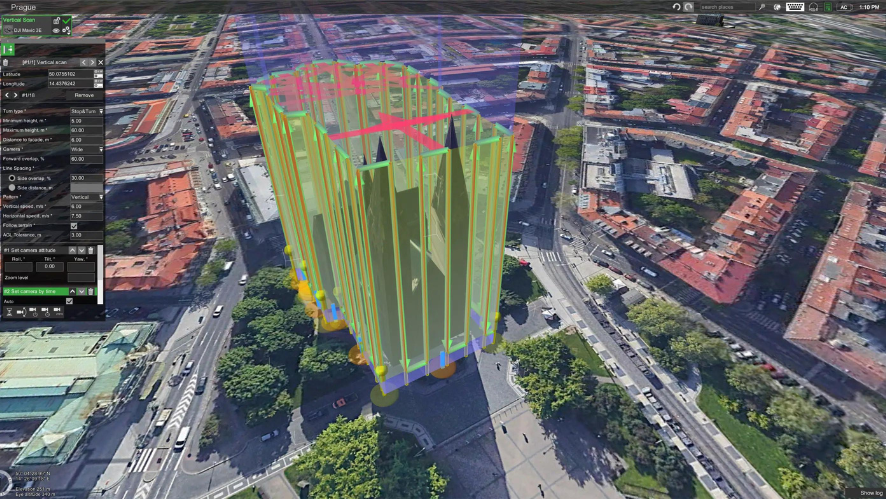

Flight Planning

Flight plans are drawn up based on the information gathered during the assessment phase and the capacity of the inspection team (i.e. available drones and pilots). After assessing the ground sample distance (GSD) required by the client and the battery capacity of the drones, the maximum area that can be covered per flight can be confirmed. These flight plans are imported into the DJI Pilot 2 and UgCS apps, helping to prepare drone operators for execution.

Data collection

At this point, the inspection team should have the necessary information and flight plan to start the operation. It is recommended to have several batteries and the inspection team should ensure that the batteries are changed and recharged regularly to optimise the workflow. Depending on the size of the solar panels and the flight plans, inspection teams can usually perform up to 25 flights and collect over 6,500 images per day.

The best drone for solar panel inspection

The DJI M300 RTK is DJI’s premier commercial drone for inspection and, with a variety of functions and capabilities. With a maximum payload of 2.7kg, the Matrice 300 has one of the highest endurance of any DJI aircraft capable of delivering flight times of up to 55 minutes (without payload).

DJI Matrice 300 RTK: A new standard in the enterprise drone industry. The Matrice 300 RTK is DJI’s latest business drone platform, and is inspired by the latest avionics systems. It offers a flight time of up to 55 minutes, advanced AI and a drone status management system, among others. The M300 RTK redefines what you would expect from an Enterprise drone thanks to a leading combination of smart features, high performance and reliability. The drone’s maximum flight time is 55 minutes (without payload) or 31 minutes when it has its maximum takeoff weight of 9 kg (6.3 kg drone + 2.7 kg payload). When carrying the new H20T sensor, the Matrice 300 RTK can stay in the air for up to 42 minutes (hovering).

Drones can offer faster and more efficient response time for professionals in the area, monitoring and quality assurance. At HPDRONES we will be happy to meet your requests and advise you throughout the process in order to choose the best drone to optimise your work.