DRONES OIL AND GAS INDUSTRY

Internal and external inspections

APPLICATIONS

Drone solutions are transforming the oil and gas industry, minimizing risk and reducing costs and downtime while protecting asset integrity.

- External inspections (examples: stacks, offshore RIGS, FFSOs, drilling vessels, oil tanks, storage tanks, refineries, methane detection and monitoring, among others).

- Internal inspections (examples: oil wells, tank inspections; pipeline inspections, offshore platforms, jackups and drillships, FCC units and cokers, damage analysis, among others).

Risk reduction

Protect workers from hazardous locations and materials while quickly addressing asset issues.

Maximum uptime

Keep operations running while conducting critical inspections using a variety of cameras and sensors.

Reliable data

Obtain detailed aerial data and quickly identify asset anomalies through repeatable and automated workflows.

Key benefits of production and refinery management

Routine drone inspections and safety monitoring improve efficiency without disrupting operations or compromising personnel safety.

- Facility and equipment management: Quickly and remotely inspect, map and monitor facilities such as stacks and cooling towers from the ground without interrupting operations.

-

Leak detection and repair (LDAR): Identify leaks quickly and accurately using drones equipped with specialized sensors, keeping personnel safe and enabling timely decisions.

-

Safety and security: Conduct regular facility patrols and routine security inspections with automated drone flights, seamlessly documenting key findings and critical issues.

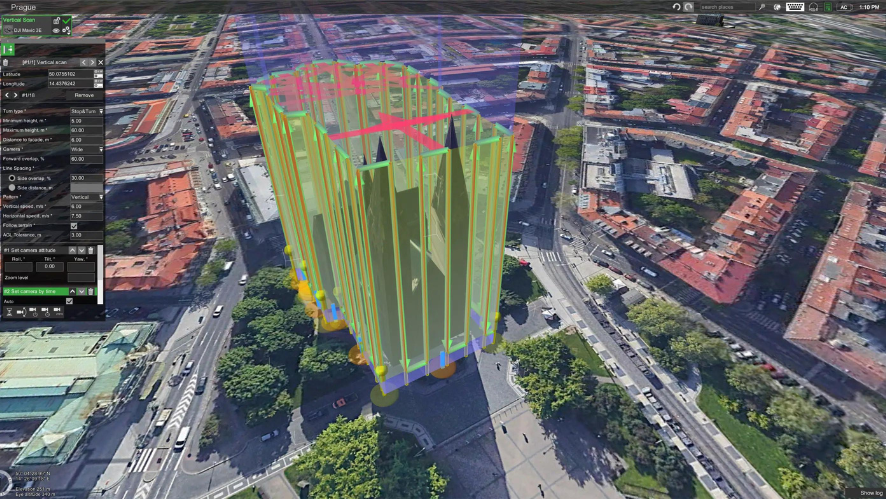

- Asset scanning: Build high-definition 2D maps and 3D models of facilities and vertical structures using drones at survey level, illustrating inspection results digitally.

General inspection

How drones power general inspection

The drones are deployed flexibly to quickly obtain an overview of the pipeline network while capturing details with a sensor zoom.

Digitize inspection results by deploying drones to obtain a live view of the pipeline network to collect evidence of illegal activities and keep the images on file for record keeping and status comparison.

Augmenting traditional inspection with drone information improves efficiency and protects workers from hazardous environments.

Leak detection and repair

Leaks compromise the safety of the site and surrounding communities.

The location of the leak can be difficult to identify, let alone acquire a reading of the leak concentration.

Personnel on the ground cannot quickly visualize the magnitude of the leak or predict its evolution without an overview.

Drones equipped with gas detector payloads can quickly scan large areas and identify the location of the leak so that it can be addressed immediately.

Drones can help personnel determine the extent of the leak, while sending aerial information that helps monitor on-site repairs.

Progress monitoring

It is difficult to keep track of oil and gas facility construction projects, as they are often dispersed, which means that more work crews have to be moved.

Fixed cameras on site cannot cover the entire site in detail, so they do not capture critical information about progress.

Large amounts of video images can drown out critical details, making it difficult to track areas.

How do drones help monitor progress?

Drones can create accurate 2D maps and 3D models of the site on demand. The 3D models can be used to track dynamic changes or daily progress.

Data collection

- Oil and gas construction projects often span long distances, making site survey and general data collection difficult and inefficient with hand tools.

- Resource exploration requires a continuous flow of data from a large area, and failure to obtain timely equipment status can result in inaccurate data.

- Drones are flexible, compact yet powerful, and provide survey-level data of large areas efficiently.

Data collection

- Oil and gas construction projects often span long distances, making site survey and general data collection difficult and inefficient with hand tools.

- Resource exploration requires a continuous flow of data from a large area, and failure to obtain timely equipment status can result in inaccurate data.

- Drones are flexible, compact yet powerful, and provide survey-level data of large areas efficiently.

ENTERPRISE SOLUTIONS

COMBO MATRICE 300 RTK

1x DJI Matrice 300 RTK

6x Battery

1x Charger

1x Zenmuse H20T

FREQUENT QUESTIONS

Why should you consider drone technology in your inspections?

It is part of their role to check when a drone can be used to collect data instead of traditional methods such as rope access. Improve your company’s overall efficiency through safer, more effective and cost-efficient recommendations.

Do drones compete with traditional inspection methods?

The answer is no. The use of drones enables fast and efficient inspections where high quality data can be obtained in high risk environments. Once the initial inspection has been carried out, such as locating a fault in a wind turbine, it will always be necessary to send a worker to carry out the mechanical repair. Think of drones as part of your toolbox, where you have the power to deploy them whenever you want a quick inspection, without risk or high cost.

What budget do I need to come up with a drone solution?

We can offer you a complete drone inspection solution, including all the training, hardware, software and ongoing support you need.