The growth in the use of thermal drones.

The use of unmanned aerial vehicles (UAVs) is constantly on the rise and expanding. Much of this growth is due to the development and refinement of new features for drones. For example, the prevalence of thermal imaging is increasing significantly.

Drones that use thermographic camera equipment to detect heat, in addition to conventional video cameras, are being used for a variety of scenarios. From fire detection to search and rescue missions and power grid inspections, the insertion of thermal drones could be the answer to an ever-growing list of important jobs in all sectors.

What are the best DJI drones with a thermal camera?

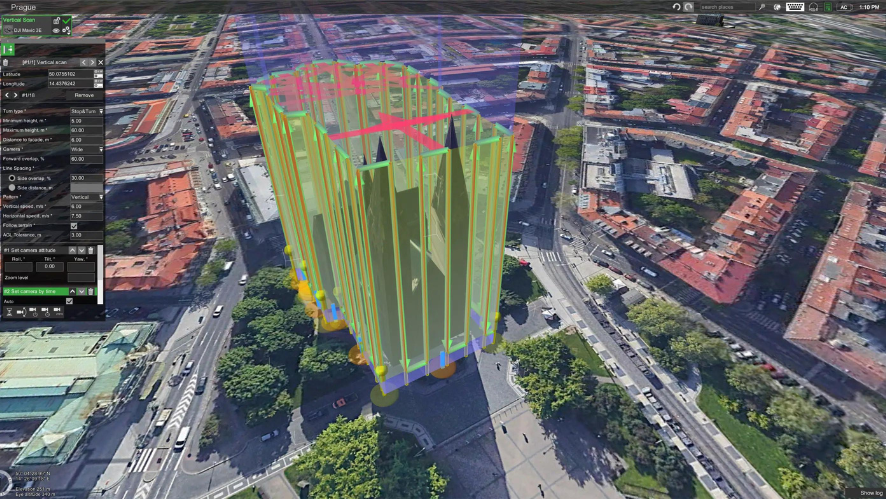

DJI Matrice 30T – The M30T is a rugged drone built to withstand the elements and designed to be highly portable, despite its impressive sensor payload. Camera resolution of 640×152, 30 fps. The M30T’s control system is especially advanced, with a 7-inch widescreen display on the dual-stick control system designed for use by corporate drone pilots.

DJI Mavic 3T – The DJI Mavic 3 Enterprise Series redefines the industry standard for small commercial drones. With a mechanical shutter, 4/3 sensor, 56× zoom camera and RTK module for centimetre-level precision, the Mavic 3E takes mapping and mission efficiency to new heights. A thermal version is available for firefighting, search and rescue, inspection and night operations.

DJI Matrice 300 RTK – The M300 RTK is the latest in commercial drone technology, with the adaptability to carry up to three payloads simultaneously. At most, the drone can be equipped with one ascending gimbal and two descending gimbals. The M300 RTK uses a new display system, incorporating more information on the main screen, to help the drone operator get around possible obstacles. Equipping the M300 RTK with a Zenmuse H20T or H20N as one of its payloads allows users to capture unprecedented levels of high-resolution thermal information.

DJI Matrice 350 RTK – Robust in construction, the Matrice 350 RTK boasts powerful propulsion, an improved IP55 rating and excellent flight performance, a payload of up to 2.7 kg and a maximum altitude of 7000 m, allowing it to effortlessly tackle a wide variety of challenges. The Matrice 350 RTK adopts DJI O3 Enterprise Transmission, which supports 1080p HD live transmission with three channels and a maximum transmission distance of 20 km.

Thermography: how does it work?

When considering the present and future of thermal imaging drone technology, it’s worth delving into the technical principles that make thermographic cameras work. Understanding how thermal imaging equipment works can inspire more effective use of the technology and new deployment approaches for thermal drones.

Heat

Heat, also known as infrared (IR) radiation, is simply the vibration of atoms. Objects emit a heat signal based on their movements, i.e. the more movement, the hotter the object. Thermography is the process of studying these heat signals and putting this knowledge of thermal images to practical use.

Humans can feel heat, but they can’t see infrared. This is because this radiation occurs at an electromagnetic wavelength that the eye cannot detect. Thermal cameras are designed to transform infrared signals into something visible to humans.

How do thermal cameras work?

Thermal cameras use specialised lenses that capture infrared frequencies, along with thermal sensors and image processors to render the results in a visual display. When an infrared camera is mounted on a drone, the device is usually placed on a gimbal, which stabilises the image and allows the lens to rotate 360 degrees.

The thermal sensors of these advanced cameras, technically known as microbolometers, have received remarkable upgrades in recent years. Today’s options don’t require the exotic cooling materials used in the past, making them much more affordable.

The thermographic cameras on drones can detect the surface temperature of many objects, but there are exceptions. For example, highly polished, shiny and reflective objects don’t absorb much heat – they have what is known as low emissivity. These are difficult to detect on thermal cameras. High-emissivity objects such as wood, concrete – and even people – are easy to analyse.

Reading and processing thermal images

Once thermal information has been captured using infrared cameras, this thermal data is displayed on a screen as a conventional image for operators to examine.

Using thermal imaging software, users can change the colour palette used to represent the heat of the scene. Each display is useful for selecting various details of the image, and these options include:

- White Hot: Warmer objects appear lighter and cooler areas are darker.

- Black Hot: The opposite of white hot, with warmer objects appearing darker.

- Rainbow: Temperature corresponds to tones, with warm colours representing heat.

The most advanced thermal cameras offer a wide variety of views – the Zenmuse H20T offers 12 separate color palettes.

DJI Zenmuse H20T – Here you have all the sensors you need in one. This is a four-sensor model with a wide-angle camera, zoom camera, laser rangefinder and radiometric thermal camera. It consists of a 20MP zoom camera, a 12MP wide camera and a 1200m laser rangefinder. Capture everything, near or far, in real or thermal color. This powerful integrated payload unleashes advanced intelligent capabilities for DJI’s industrial drone platforms. It also adds a 640 × 512px radiometric thermal camera. The camera generates R-JPEG files with embedded temperature information, allowing for more in-depth analysis.

Care to take with thermal cameras and how to protect them from possible damage.

Before you start using a thermal drone, it’s important to know some common ways in which thermal sensors get damaged and how to prevent it. Although DJI products are known for having excellent build quality and durability, thermal sensors, by their very nature, are extremely precise and well-adjusted instruments that require care when using. Improper use can cause permanent damage to the thermal sensors, leaving artifacts in the data collected.

Do not expose the camera’s thermal lenses to strong energy sources such as the sun, lava or laser beams.

Accurate thermal measurements.

Even highly effective thermal imaging cameras need to deal with a variety of environmental factors that can make it difficult to get an accurate reading of the surface temperature. This includes atmospheric conditions – too much heat, humidity, clouds, rain or snow can impede the thermal camera’s accuracy. Thermal cameras also struggle with glass, as reflective glass can capture heat from the sun, the ground or another object.

An object’s surface coating can also affect a thermal drone’s ability to take temperature readings. Corrosion or a new coat of paint can alter an object’s relative temperature reading. The relative position of the sun can also make objects of the same material look different on a thermal imaging camera.

When using a thermal imaging camera it means keeping the following factors in mind:

- Atmospheric conditions;

- The presence of smoke, dust and debris;

- Emissivity;

- Transparency;

- Reflectivity;

- Time of day;

- Angle of view;

- Distance from target;

- Amount of thermal energy;

- Roughness or smoothness of the surface.

With these characteristics in mind, it is possible to build an accurate image of the thermal properties of an object or landscape.

Advanced camera considerations

High resolution and more color display options are some of the advantages that come with high-tech thermographic camera systems. Powerful new features to consider include:

Dual camera drone payload options: Drones equipped with modern thermal imaging systems can capture several types of images simultaneously. Hybrid thermal payloads are two cameras in one, a conventional imaging system and an IR camera.

User-customized isothermal settings: Through a thermal drone control panel, users can set isotherms, which are customized temperature settings.

State-of-the-art thermal imaging software: The software used to interpret infrared images offers new features such as temperature tracking for specific objects, real-time heat updates, overlay of visible light and infrared images and much more.

Thermal imaging camera technology

Choosing a thermal imaging payload for a drone is a matter of matching the equipment’s capabilities to an organization’s use case. There are a few different factors that determine the performance of a camera system in the field. These include:

Field of view (FOV): This is a measure of how large an observable image can be captured by the camera.

Weather resistance: Measured in ingress protection (IP), this determines resistance to the elements – including moisture from rain and fog.

Spectral band: The spectral band is the electromagnetic range detectable by the camera’s IR sensor.

Thermal sensitivity: This metric denotes the degree to which a sensor can measure differences in relative temperature and is also called noise equivalent differential temperature (NEDT).

Image resolution: Rather than the size of the area the camera captures, this reflects how many pixels go into the digital image that is generated, which in turn determines the level of detail.

Use cases for thermal drones: now and in the future.

Thermal drones can serve more functions today than in the past, with more precise sensors and lower prices opening up new possibilities.

Use of thermal drones

Firefighting: One of the most common uses of thermal drones is as firefighting tools. Heat mapping from the air allows firefighters to anticipate risk factors. When working inside structures, it is possible to map possible points of failure, while in forest fire scenarios, drones can help teams intercept the progress of open-air fires.

Search and rescue: Fires aren’t the only types of disaster where thermal drones can help rescue teams. After disasters such as floods, landslides, earthquakes, tornadoes and hurricanes, thermal drones can help teams find missing victims, even at night. These thermal UAVs are also capable of tracking down individuals who have become lost.

Aerial utility inspections and mining drones: Inspecting utility infrastructure, from power plants and solar panel installations to distant power lines, is easier with drones. The use of thermal cameras alongside conventional images allows teams to observe possible risks of failure in new ways or even inspect the condition of thermal panels. No matter the size of a power plant or mine, drones can fly over the site and take readings.

Advanced agriculture: Monitoring crops and grazing livestock from the air is a potentially overlooked use for drones. Thermal imaging allows farmers to measure the heat exposure of fields and track animals, even at night. Ongoing efforts to make agriculture more efficient through the deployment of technology are a perfect match for drone deployment.

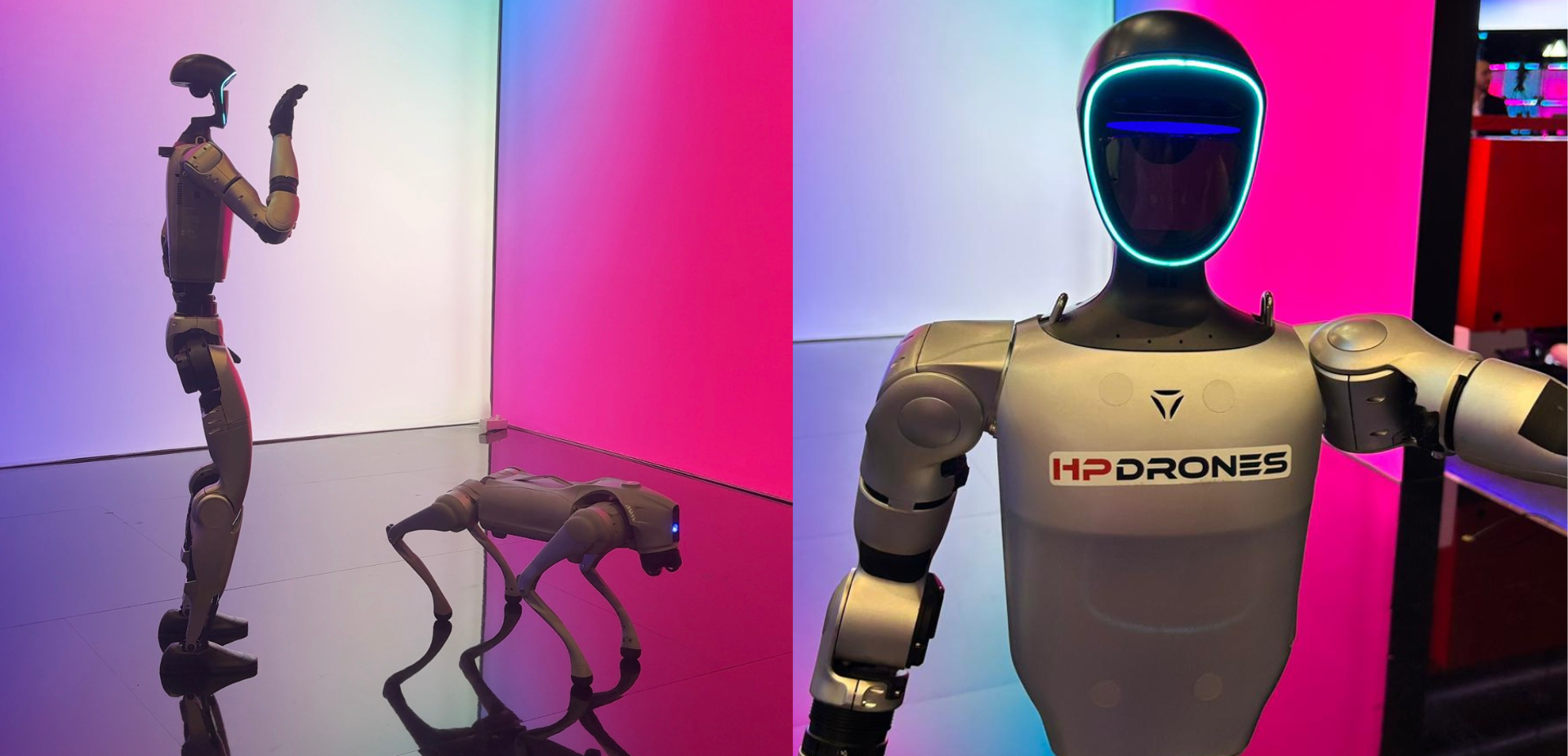

Contact us for more information! We have the best solutions on the market. Thermal drones are available, just contact our sales department for clarifications and questions.

__________________________________________________________________________________________________________________________