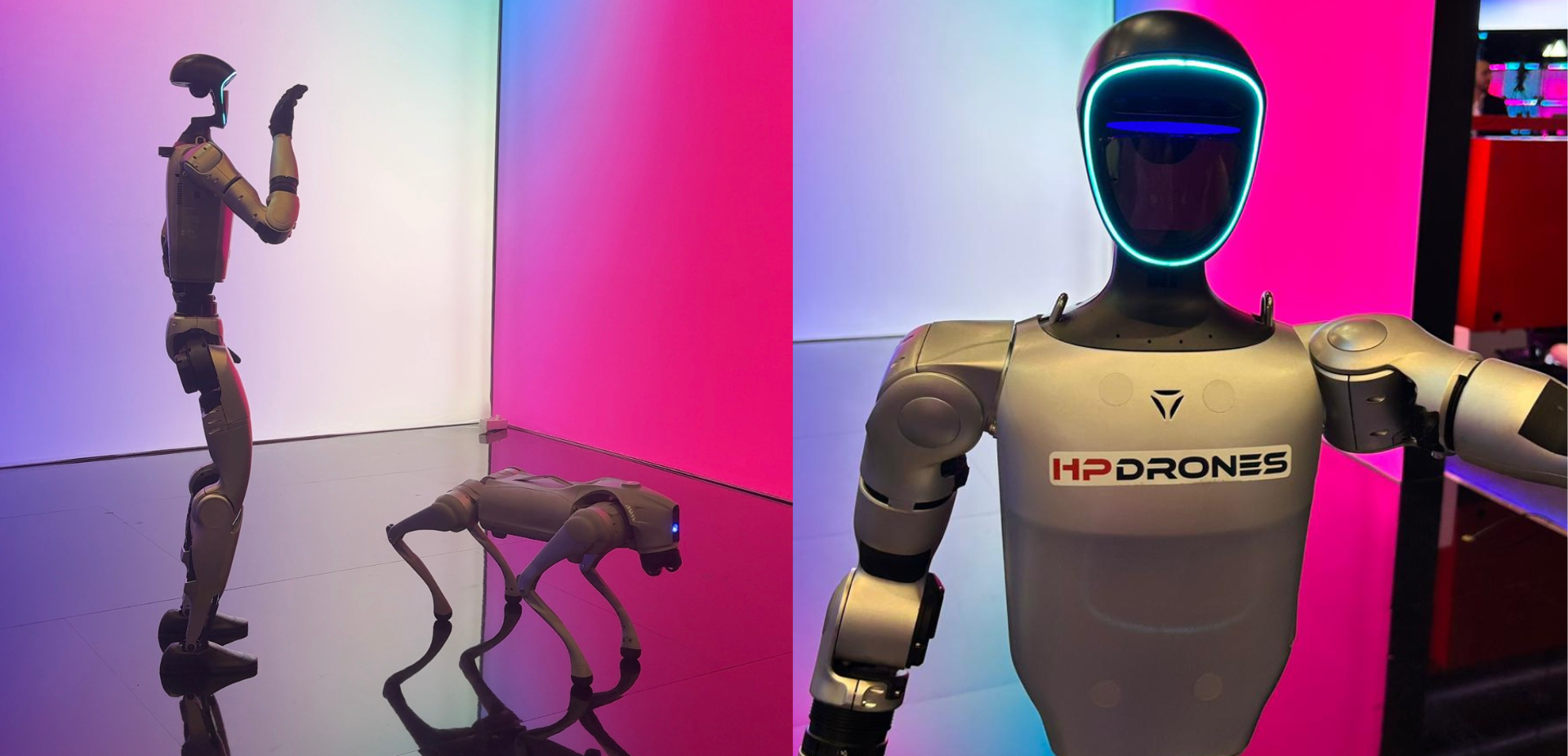

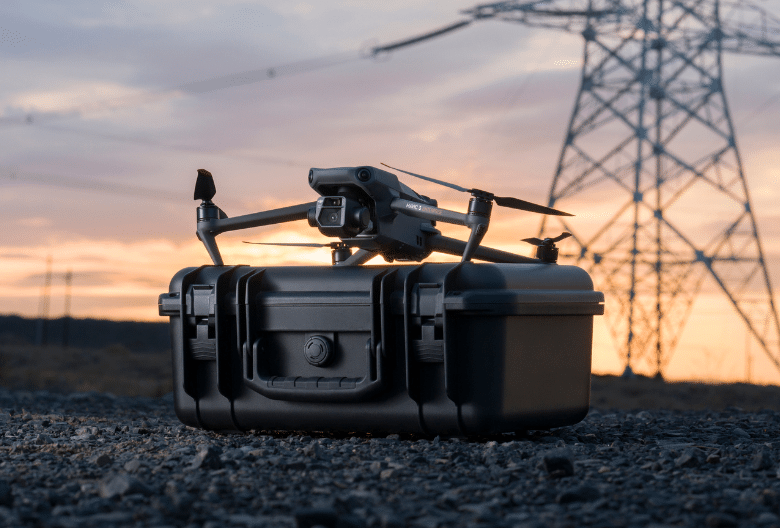

EDP and HPDRONES case study

Advantages of drones in electrical inspections with DJI drones

EDP and HPDRONES case study

Power Tower Inspection Service

The power tower inspection service comprises a set of tasks designed to assess the efficiency of structures and ensure their functionality and safety. For years, standard inspection methods required operators to climb the structures to take photographs and make diagrams, which were then analyzed by the team. This process is time-consuming and puts the operator’s life at risk.

Since drones are complex products involving many interconnected systems, it is difficult for an operator to inspect and maintain their fleet alone.

For this reason, we are introducing a new Maintenance Program, consisting of three plans and a recommended maintenance cycle, which will provide drone operators with greater safety and confidence.

Drones are revolutionizing work methods, increasing business efficiency, and effectively improving commercial results. Speed, safety, efficiency, economy, and sustainability: guarantee it all with DJI drones. HPDRONES has worked hard to achieve the best results for its customers, such as EDP Portugal.

Electrical inspections and the new era of drones

EDP (Energias de Portugal) is a vertically integrated energy company with a consolidated position in the Iberian Peninsula, both in terms of electricity generation, distribution, and supply, as well as gas supply. Created with the ambition of being a center of technical excellence, EDP LABELEC is a benchmark in the areas of engineering, preventive maintenance, and innovation. Its services cover the entire value chain of the electricity sector, from generation and transmission to distribution and consumption. Its extensive experience in high-voltage services, electrical and electromechanical testing, inspections, research, certifications, consulting, and environmental services has earned it growing national and international prestige.

EDP

Since 2022, EDP has been using DJI drones such as the Matrice 350 RTK, Mavic 3 Enterprise, and Mavic 3 Thermal for power line inspection. Before the use of drones, EDP Labelec’s line inspections were carried out solely with manned aerial vehicles, i.e., helicopters. In this context, power line inspection data is collected with the help of an aircraft carrying a set of sensors (LiDAR, RGB cameras, infrared thermal cameras, and ultraviolet masters) that allow operators to gather all the necessary information on the technical condition of network assets and the state of repair of the strip where the power lines are installed.

Drones are revolutionizing work methods, increasing business efficiency, and effectively improving commercial results. Speed, safety, efficiency, economy, and sustainability: guarantee it all with DJI drones. HPDRONES has worked hard to achieve the best results for its customers, such as EDP Portugal.

EDP Labelec currently faces three major challenges. The first relates to the ability to manage the two types of inspection methods, namely drones and helicopters, in such a way as to take advantage of the benefits of each methodology, creating synergies in their combined use. The second major challenge relates to the processing of the information collected, which in the case of drone inspections, and in particular the RGB component, tends to be of greater volume. The third major challenge concerns the legal and regulatory framework for the operation of remotely piloted vehicles, i.e., the balance between the widespread use of this type of equipment and ensuring the safety of people not involved on the ground and other aircraft.

The organization’s objective is to use unmanned aircraft to increase the versatility of its operations, as the current methodology offers advantages over the traditional one. Among the advantages are:

● Resource mobilization and product delivery: In an emergency, the time between the order to inspect a line and the availability of the data collected to support decision-making is very short.

● Operational flexibility: Drones enable data collection in locations with complex terrain that could pose challenges for conventional aircraft.

● High data quality: With advances in drone technology and DJI sensors, it is possible to provide customers with highly accurate, high-quality data. This facilitates early detection of infrastructure problems, thereby increasing process efficiency.

Enhance your work with the DJI Mavic 3 series and DJI

Matrice 350 RTK

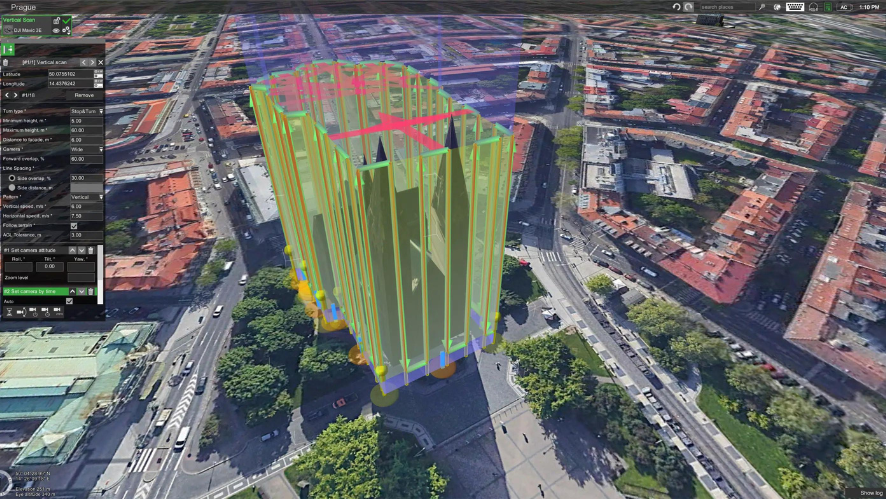

The Mavic 3T has been used to collect RGB and thermal data. This equipment allows for visual analysis of infrastructure and the electrical grid, such as detecting hot spots, component damage, and even numbers and codes on elements. For André Coelho, obtaining RGB data has been a benchmark of the highest quality, and it is clear that the images recorded allow for an unprecedented level of detail. Another piece of equipment used is the Matrice 350 RTK, equipped with a LiDAR sensor to obtain high-quality point clouds, enabling the production of 3D indicators based on terrain morphology, which are used to monitor fuel strips associated with the network.

It is necessary to implement a methodology that allows for the daily collection of data from large sections of the electrical grid, while maintaining the quality of the data obtained. As for the Matrice 350 equipped with the Zenmuse L2, this combination has features that allow for very satisfactory performance for the customer:

● The Zenmuse L2, with horizontal and vertical accuracy of 5 and 4 cm respectively at 150 m, allows you to fly the line at a safe height (away from obstacles and without loss of connection) and using automatic missions planned in the office;

● The battery life, together with the wind resistance of the equipment, allows data to be collected in more complex weather conditions with little loss of performance;

● The reliability of this equipment guarantees continuous operation throughout the year without unexpected breakdowns or maintenance.

● Data processing with DJI Terra software saves time in the office, simplifying processes in terms of obtaining point clouds and georeferencing them, as well as eliminating noise in them.

As for the Mavic 3T, its strengths are as follows:

● The small size of the drone, combined with the quality of the RGB and thermal sensor and the reliable obstacle detection system, allows the drone to be positioned in all frames predefined by the customer, even in the presence of obstacles such as tree branches or other power lines;

● The battery life allows you to collect data from a large number of service stations, contributing to a very satisfactory daily data volume;

● The reliability of the equipment guarantees continuous operation throughout the year without unexpected breakdowns or maintenance;

Inspecting energy infrastructure using drones makes the operation safer and reduces its environmental impact. It is distributed throughout the territory, including environmentally sensitive areas with vulnerable ecosystems and endangered species. EDP’s focus is on sustainability, and aspects such as the preservation of environmental values are a priority for the company, which has already been considered the most sustainable organization in the world in its field.

DJI Enterprise drones have helped professionals in various industries perform visual, thermal, and LiDAR inspections, zoom camera surveys, photogrammetry, and mapping. This allows energy companies to manage power lines more quickly, efficiently, and safely, without having to shut down towers during inspections. Performing an automated inspection with a drone can save between 30% and 50% in costs and time. Drones identify risks to asset integrity and report response measures.

Accurate and efficient data collection. Greater efficiency

and better results

For the EDP group, the use of UAVs involves collecting a very significant volume of data on a daily basis, which allows for a constant workflow of data delivery with distinctive quality, whether in visual analysis or in the LiDAR component.

According to André Coelho, director of asset inspection at EDP, “the evolution of DJI drones in terms of their ease of use in the context of power line inspection has been remarkable. The orientation of some equipment and sensors towards this type of operation has been evident. In addition, there has been a favorable evolution in the robustness of the equipment, making it suitable for intensive operations with high pressure on productivity. In this sense, they have been a very important tool for the activity we carry out in the field of power line inspection.”

According to our EDP project manager, “feedback has been very positive regarding the quality of the products obtained with DJI equipment. The aforementioned equipment allows us to collect a significant amount of data on a daily basis, which makes it possible to maintain a constant flow of data delivery, something that is very important to the client. In addition, the data collected is of high quality, both in terms of visual analysis and LiDAR.”

Challenges and objectives that lead to the search for a

solution with drones

There are three main objectives guiding the development of drone activity for EDP. First, to increase efficiency in order to offer the most competitive service possible. This allows them to do more and better with the same resources, driving more effective management of the electricity grid with the social and economic benefits that this entails. Last but not least, they want to continue making progress in reducing the safety risks of line inspection activities, and they believe that drones will undoubtedly contribute significantly to this.

Save time and increase efficiency

Reduced time and efficiency in data collection are some of the main advantages in power line management. Even with vegetation near the lines, drones are able to quickly map and create 2D and 3D models. This is a case that EDP has been able to observe closely. For the team, drones have made it possible to increase efficiency by collecting more data on the asset being inspected and, therefore, obtaining better results from the equipment. It is possible to collect more data in a more automated way, with less effort and in less time.

Power line inspection is a complex activity involving several phases and challenges. Increased operational productivity is achieved by taking advantage of various small opportunities throughout the value chain. Drones have been an excellent tool for contributing to the overall efficiency of the activity, and this is yet another case of successful development.